Description

Introduction

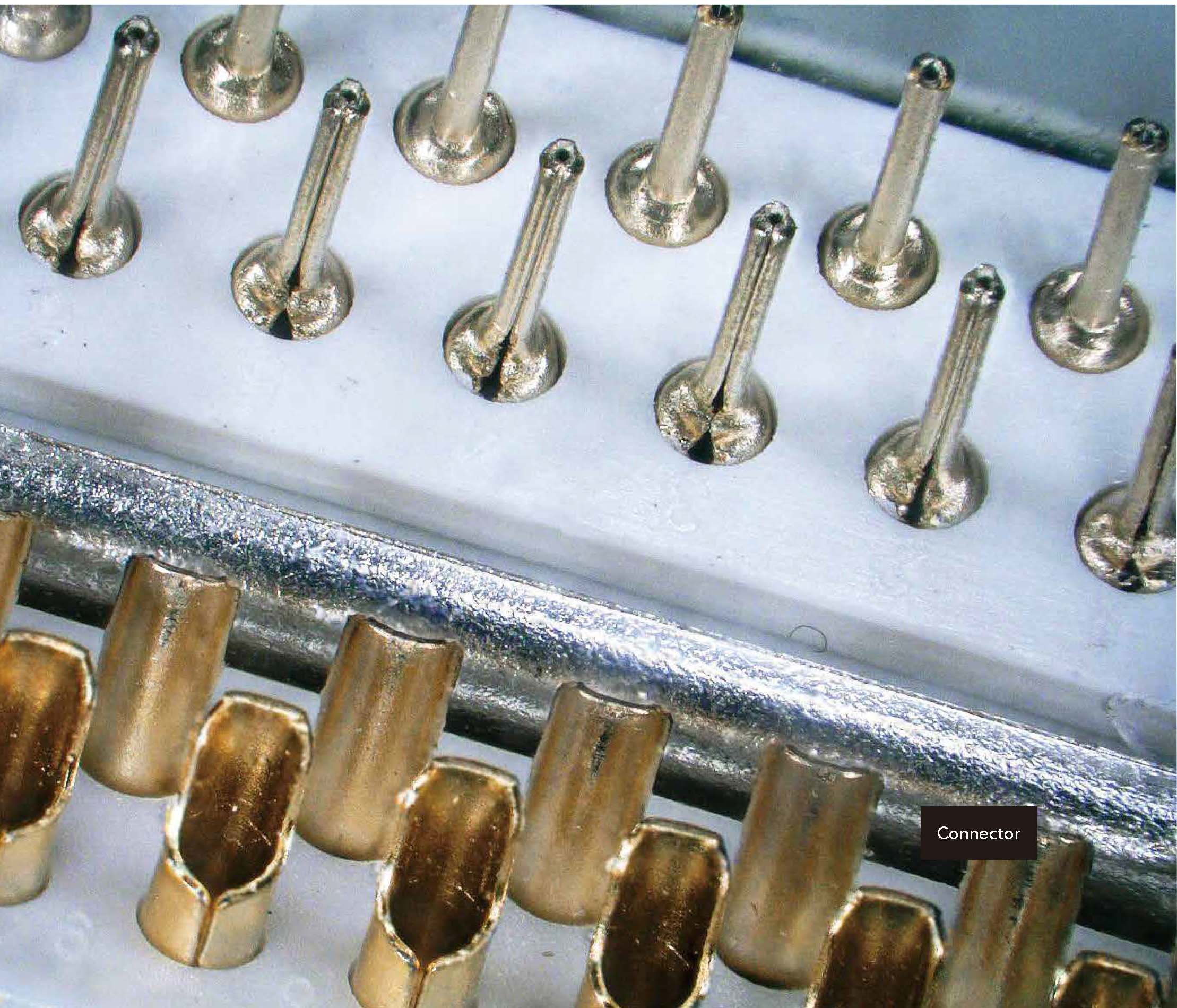

RO3D series 3D digital microscopes are mainly used in the observation, measurement and analysis of surface microscopic topography. Unlike traditional optical microscopes, RO3D has a larger depth of field, wider field of view, and higher magnification , more comprehensive observation angle, better lighting mode. With the blessing of the image processing algorithm “KM-DSIM” developed by ourseleves, RO3D is sufficient to cope with various challenging observation scenarios. RO3D series 3D digital microscopes have been widely used in intelligent manufacturing, aerospace, military, 3C electronics, semiconductors, automobiles, new energy, new materials, medical and pharmaceutical industries.

Advantages

|

Deep Compositing

“KM-DOFO” self-developed depth synthesis algorithm realizes clear overlay imaging within a wider depth of field. |

|

Image Stitching

KMHI self-developed “KM-IMHI” image stitching algorithm to achieve 4.9 billion pixel 2D stitching and 3D fusion. |

|

|

Holographic Lighting

Obtain image information under full-angle illumination and generate a single hologram, and you can freely choose the best observation angle |

|

Halo Removal

Change the lighting mode and take multiple groups of samples, eliminate the halo area and superimpose the visible area through the image algorithm. |

|

|

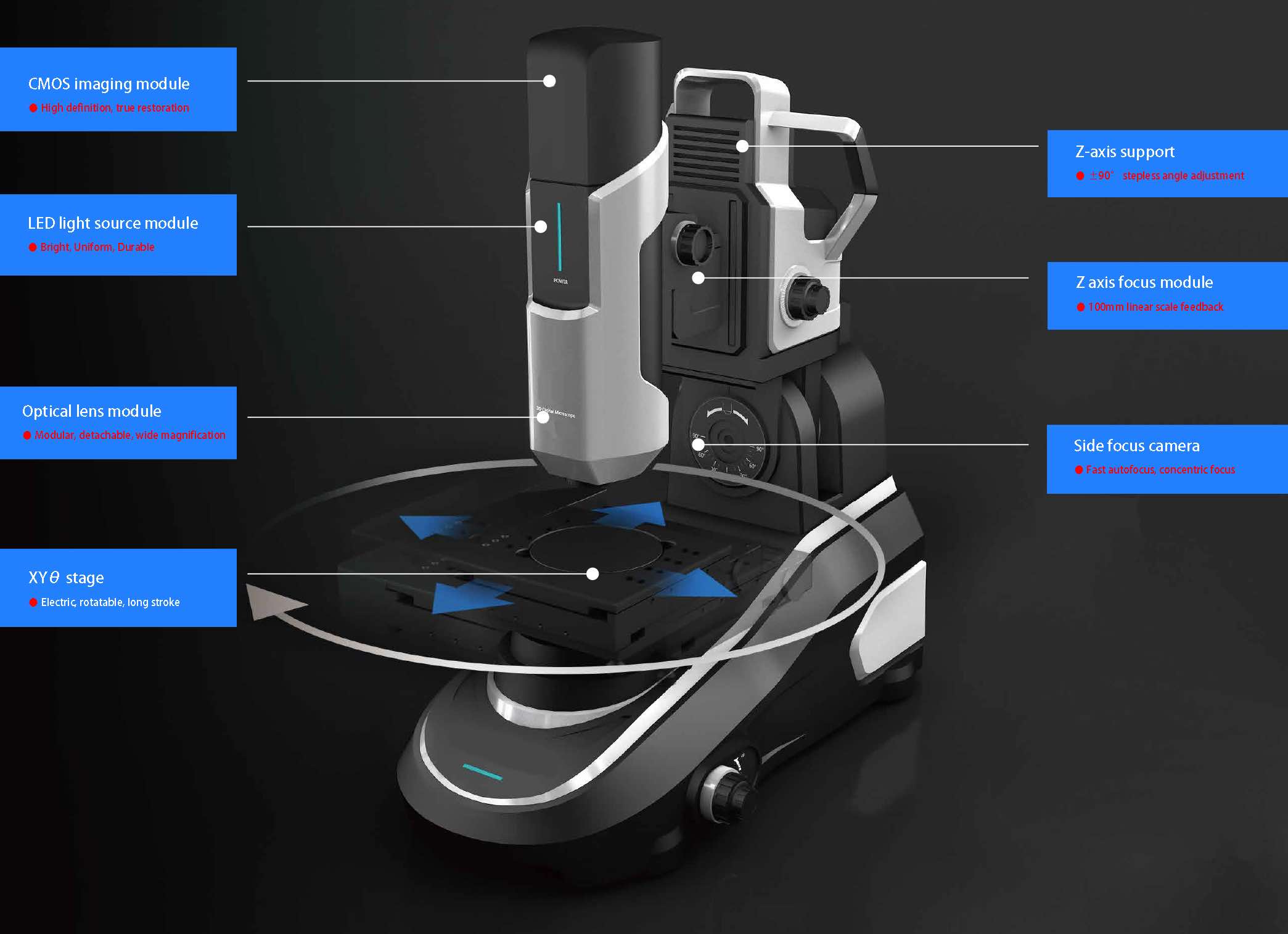

All-round Observation

The host adopts a ±90°rotating bracket structure, and the lens module can be held for free observation. |

|

One-click Image Optimization

Click to generate 12 previews of image processing effects, and flexibly select the best image optimization mode. |

|

|

Precise 3D Measurement

100nm linear scale feedback module combined with low distortion optical lens to realize precise 3D size measurement. |

|

Machine Learning and Open Systems

Machine learning algorithms make online detection more intelligent and efficient, and the open system supports secondary development. |

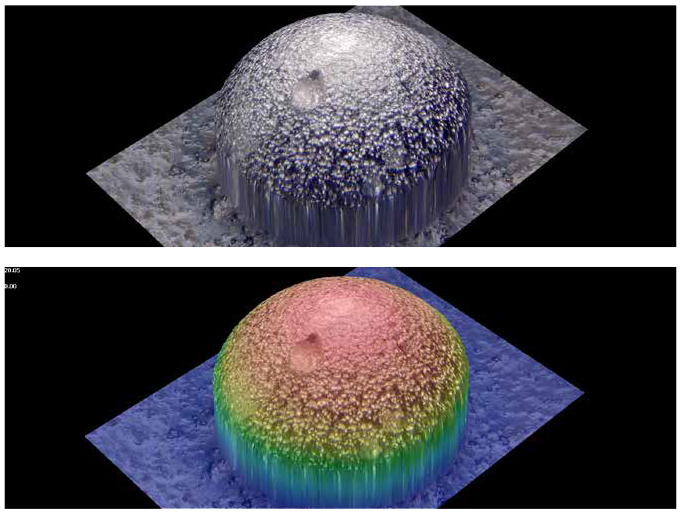

Due to the large number and small size of solder balls, the quality inspection of ball grid array package (BGA) is a task that cannot be ignored in the semiconductor manufacturing process.

Before soldering, use RO3D’s holographic lighting observation mode and precise 3D dimension measurement function to generate BGA holographic images and pseudo-color 3D dimension views, complete full-angle observation of 3D contour measurements, and avoid any slight position deviation and dimension deviation.

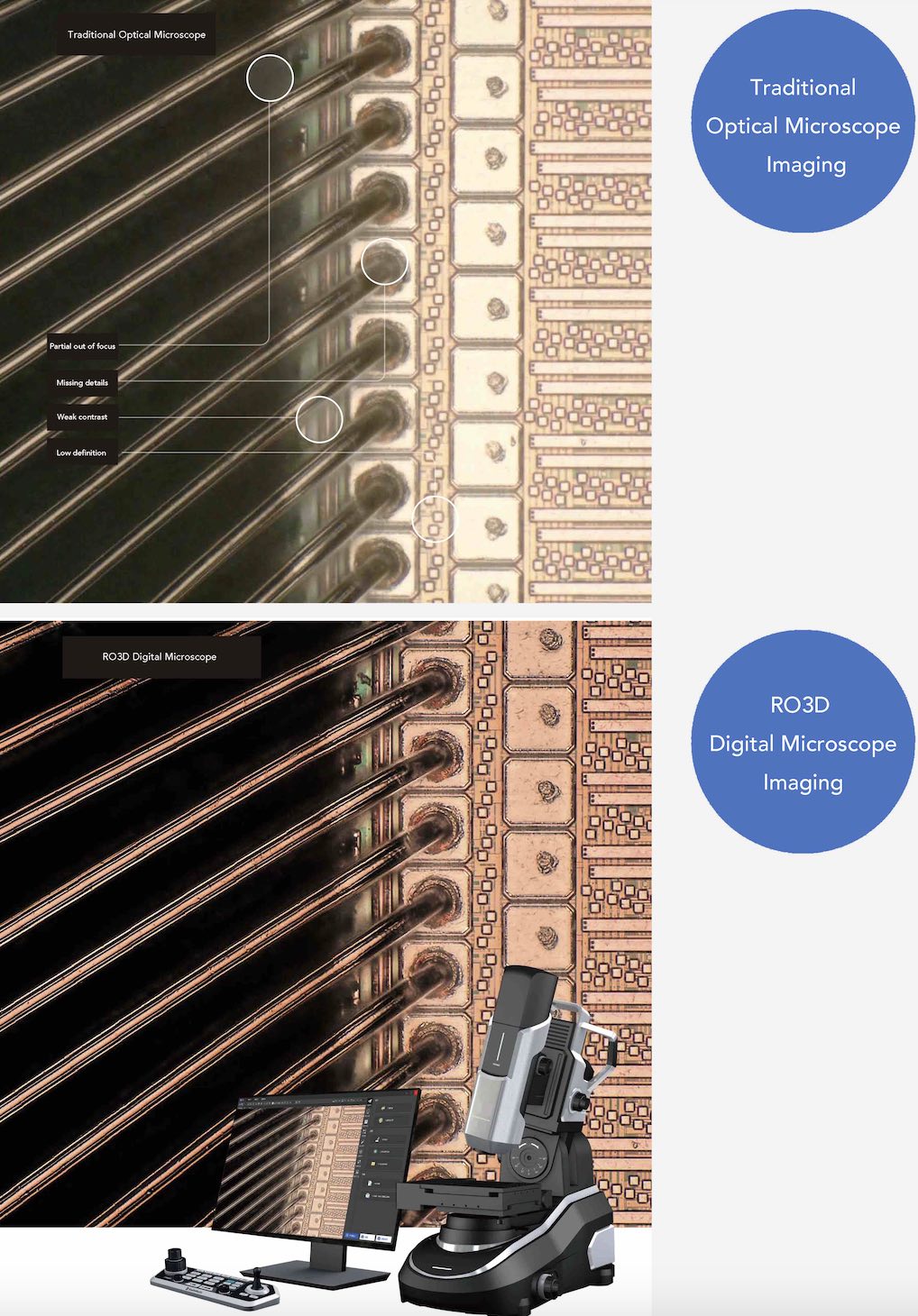

A Refreshed Visual Experience

If you have used a traditional optical microscope, then the visual experience brought by the RO3D series 3D digital microscope is absolutely brand new. RO3D completely solves the problems of traditional optical microscopes such as shallow depth of field, small field of view, low contrast and poor resolution.

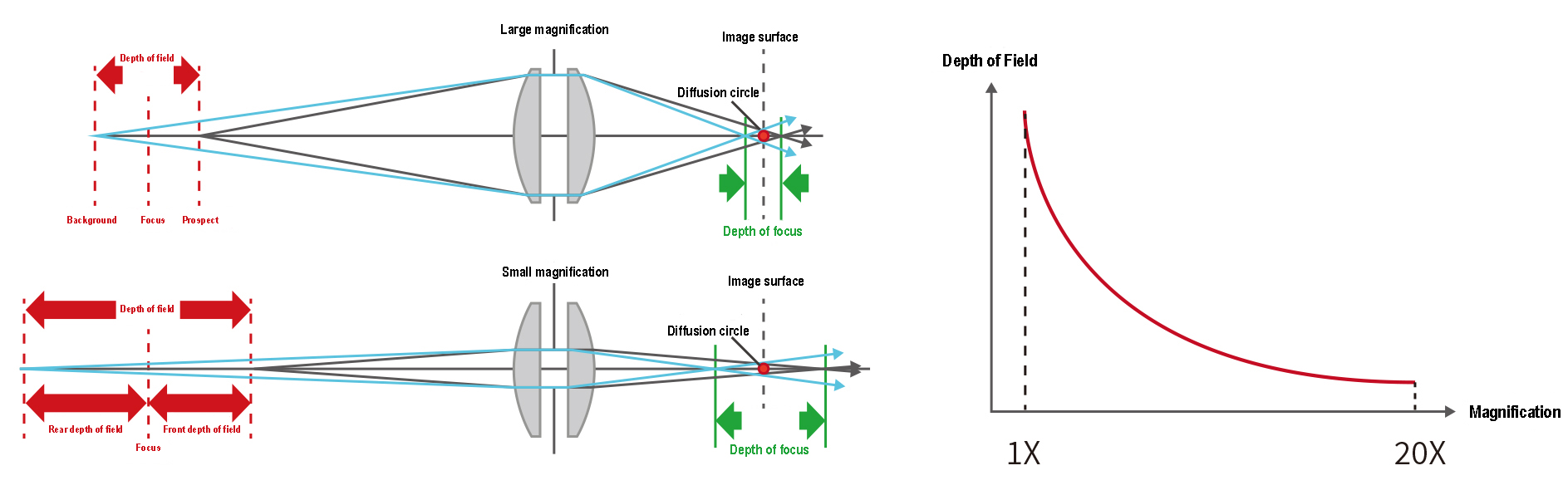

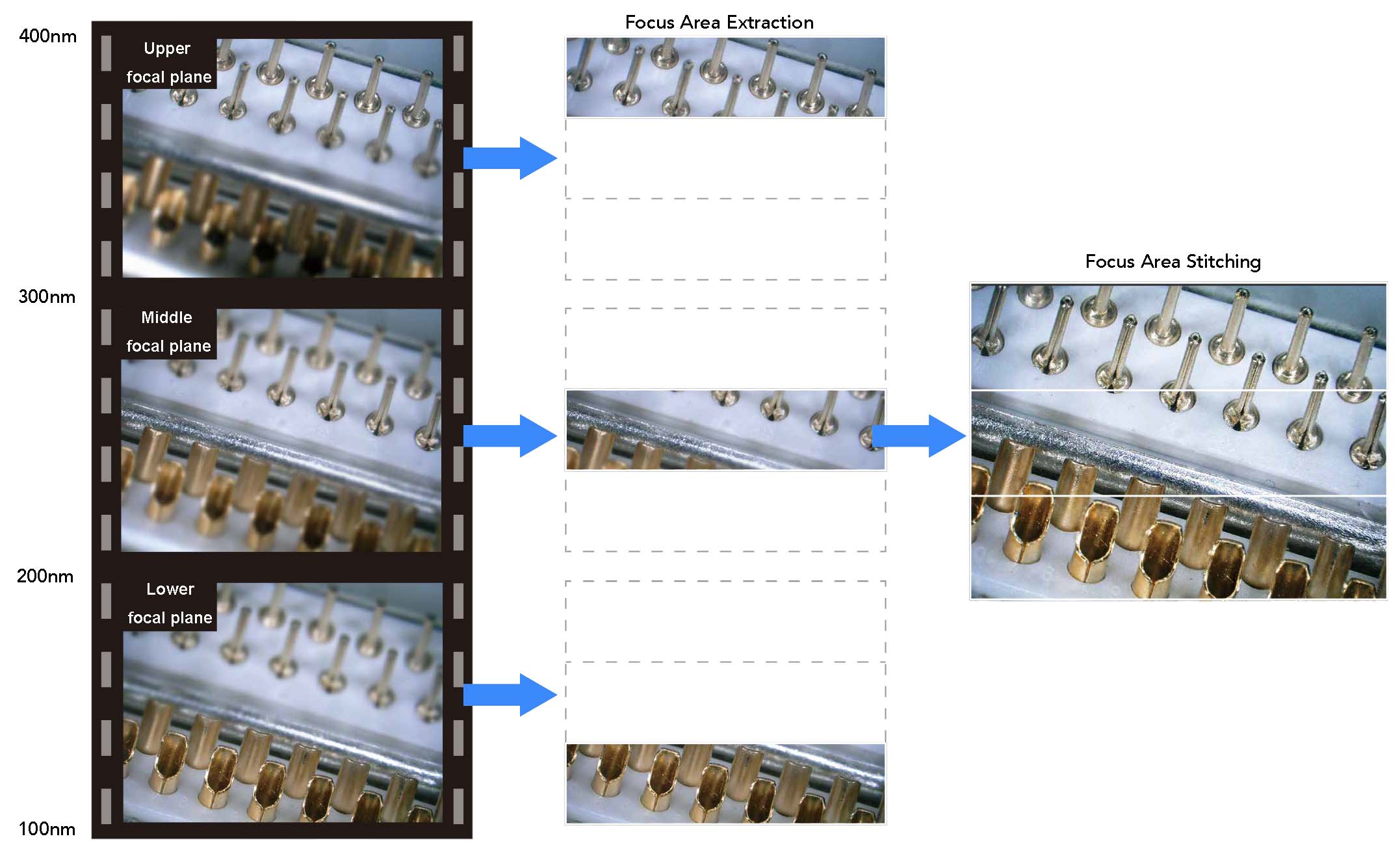

Hundred nanometer precision deep synthesis

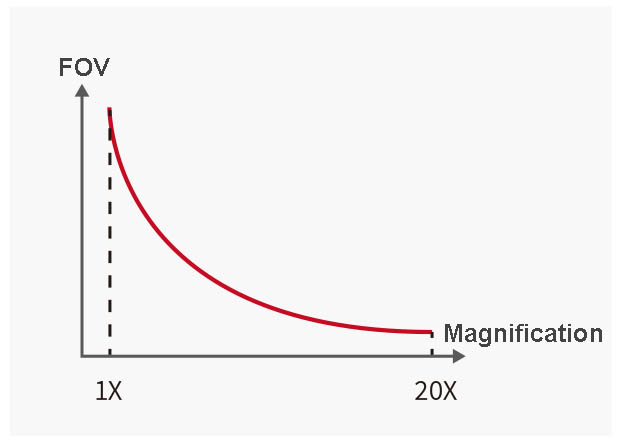

In order to improve the image resolution, a high-magnification lens must be selected, but when shooting concave-convex shapes, the image often contains a large area of out-of-focus.

RO3D has a deep synthesis function, which fuses the focus areas of multiple images to obtain high-definition images and perfectly restores the surface concave-convex structure. And it adopts equidistant shooting, controlled by the linear scale feedback module, and the Z-axis resolution can reach 100nm.

| Principle Explaination

RO3D Main Device’s Structures

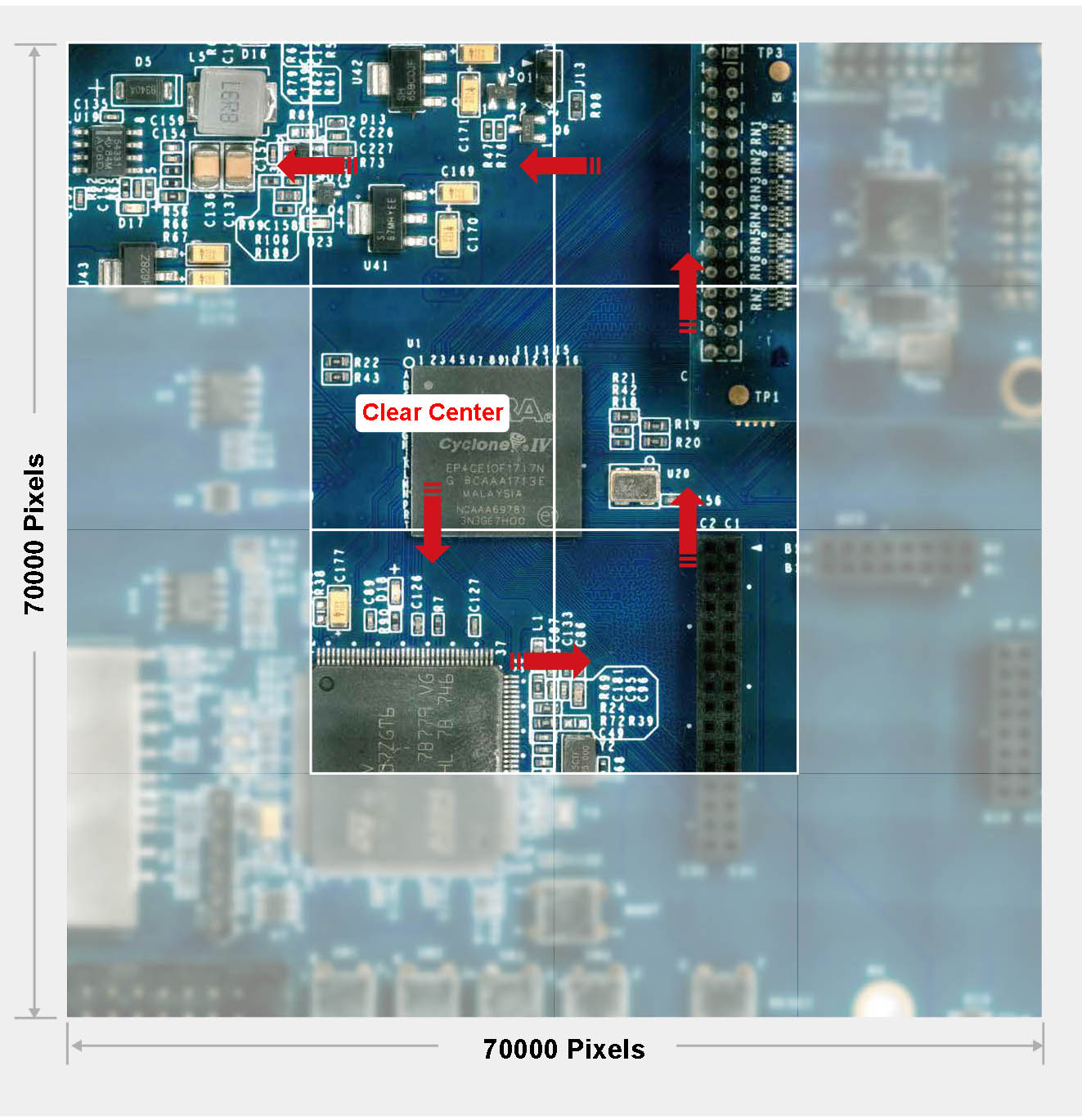

Image Stitching

| 2D Image stitching

Stitching and shooting are performed simultaneously, combined with the automatic correction function, which can eliminate optical distortion and image misalignment. The maximum size of images that can be stitched is 70000 (H) pixels × 70000 (V) pixels.

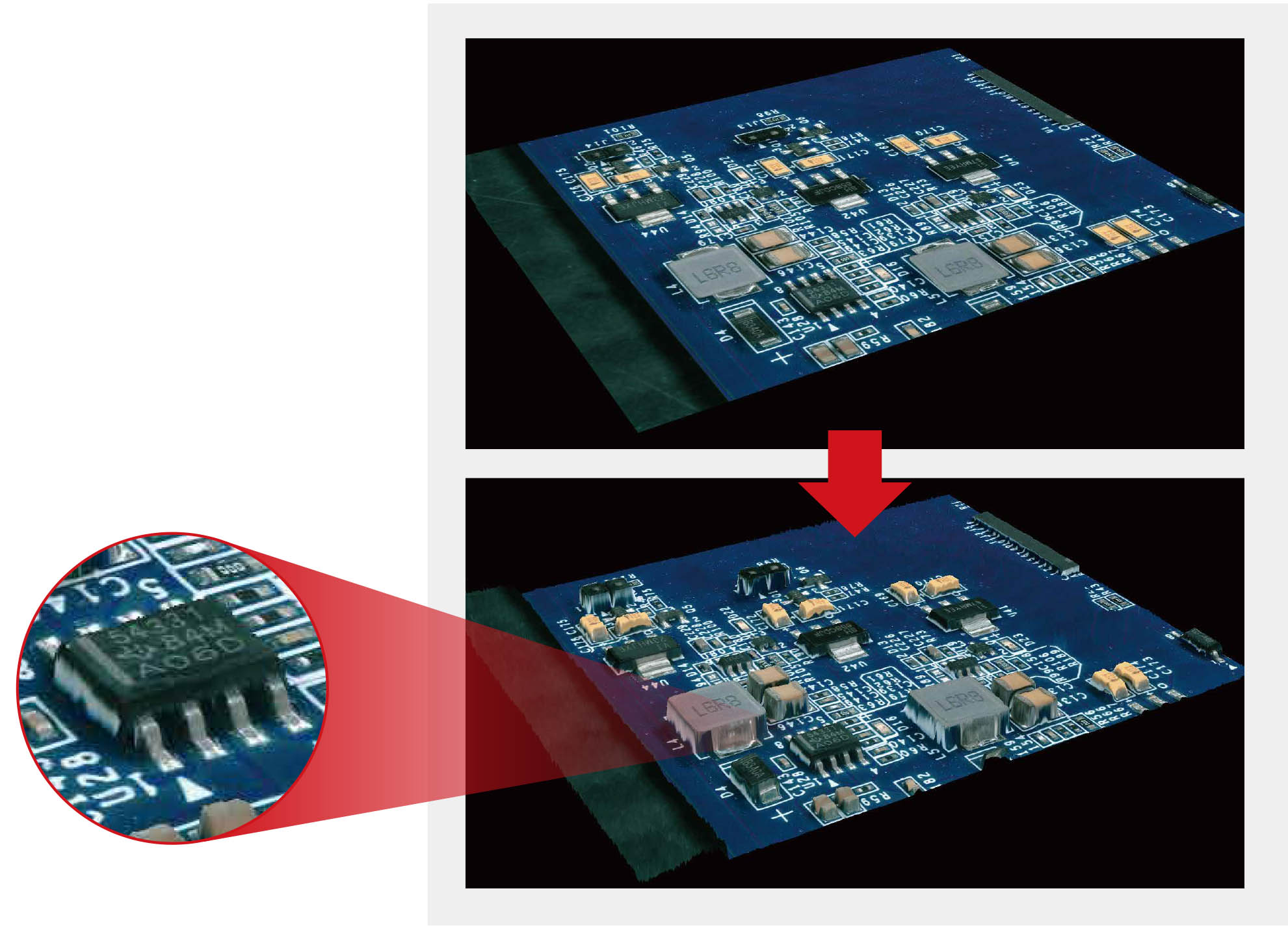

When using a high-magnification lens to observe a tiny sample, the entire picture of the sample cannot be observed due to the limited field of view.

| 3D image fusion

At the same time of 2D image stitching, deep synthesis is performed and 3D data is obtained, and the final presentation form is like a three-dimensional display of the full-frame image.

Holographic Lighting

| Light source module

The light source module of RO3D is divided into light-emitting components and soft light components. While ensuring a compact structure, the light intensity is higher, the uniformity is better, and the lighting modes are more, and there will be no problem that the measurement accuracy is affected by the heating of the light source

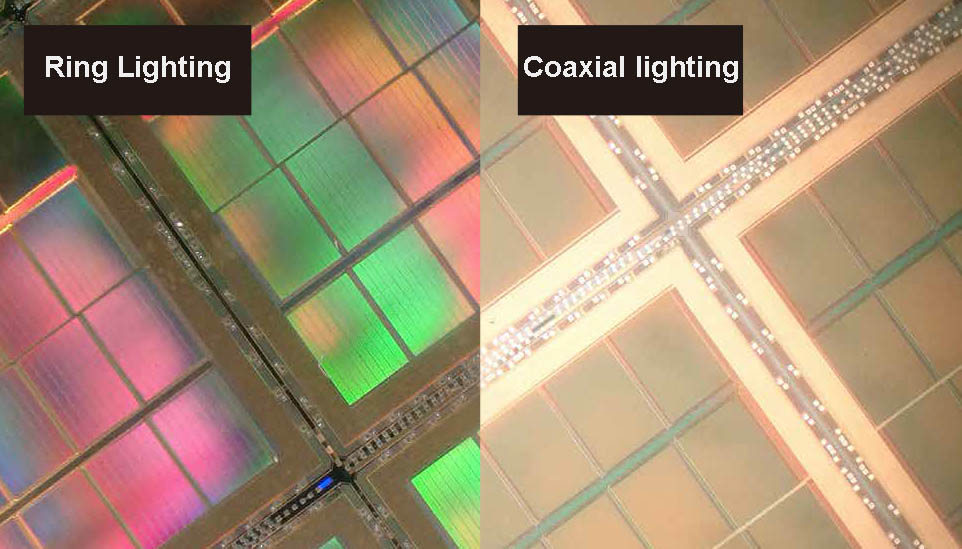

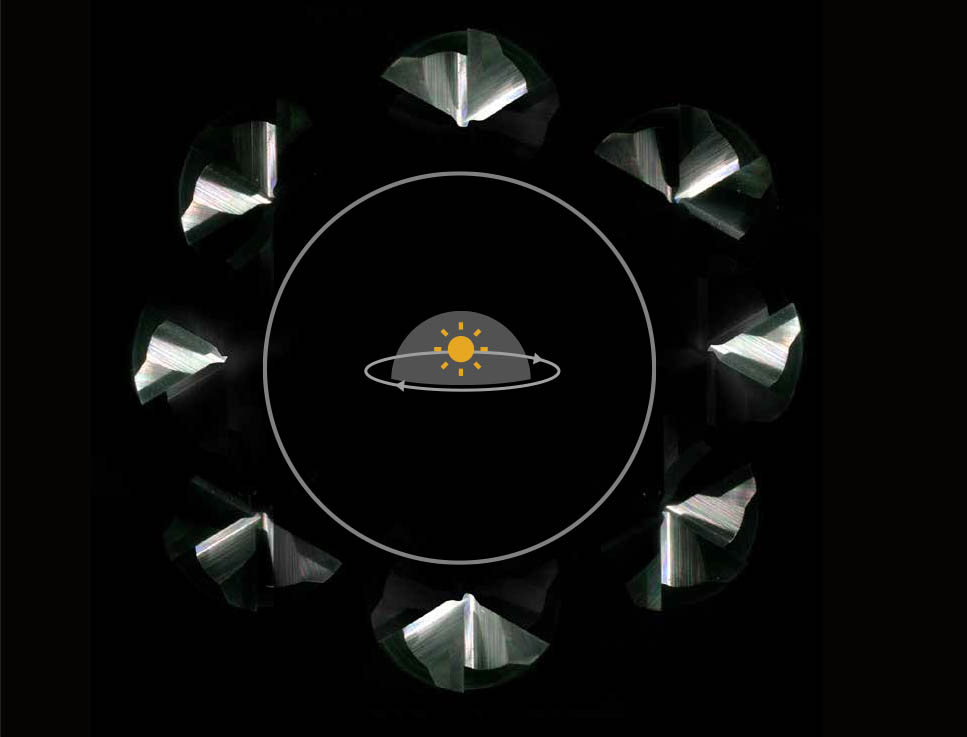

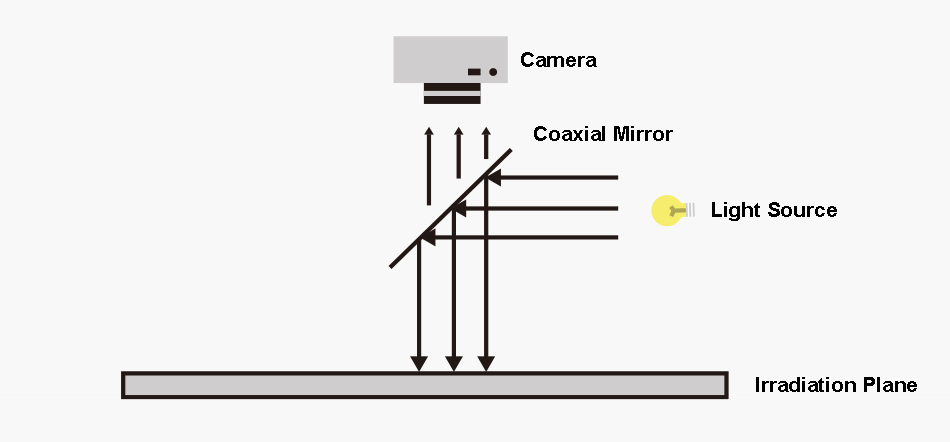

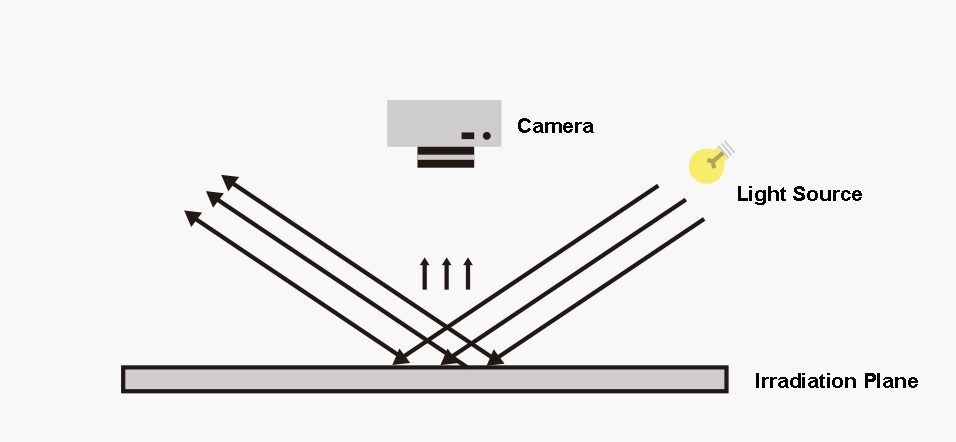

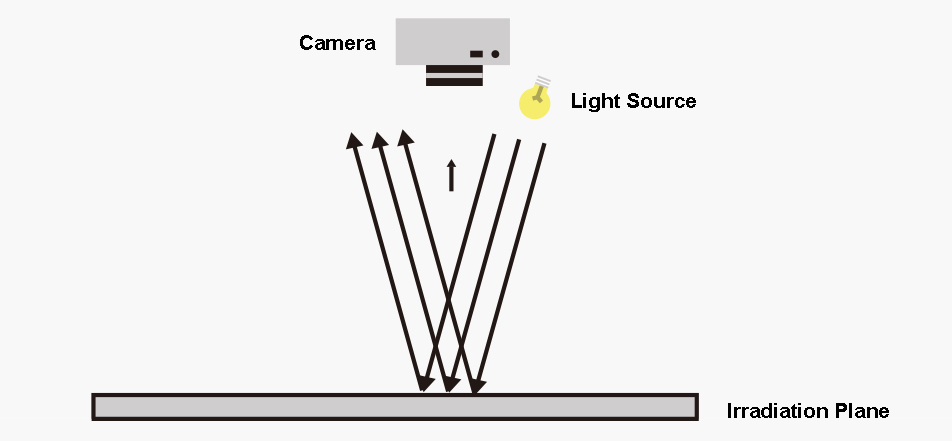

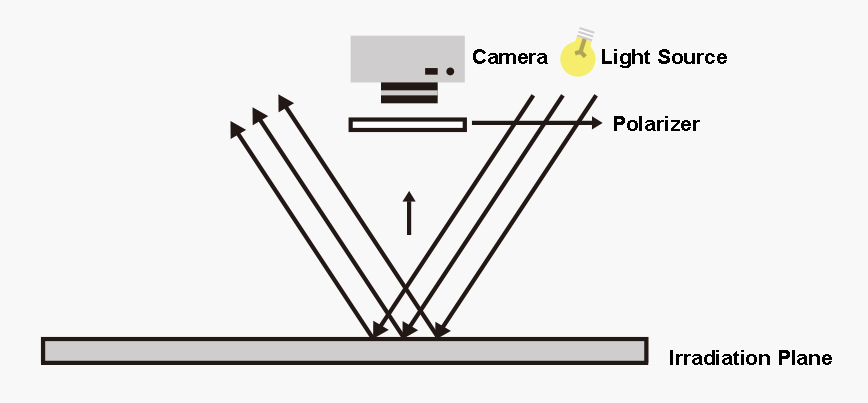

The software can independently control the switch and intensity of each beam of light, and realize various lighting modes such as coaxial epi-beam, coaxial side-beam, annular epi-beam, annular side-beam, and combined illumination.

– Ring lighting can restore the color and stain of the sample itself

– Coaxial illumination can highlight scratches & 3D imperfections on the sample surface.

– The software can control the ring light for 360° rotating lighting and continuous shooting, and analyze effective information for synthesis. Just drag the sun icon to achieve holographic lighting effects.

– Bright field

Suitable for observing the fine structure of flat and smooth samples

– Dark field

Suitable for observing scratches, scratches and dust on the surface of samples

– Side light

Suitable for observing irregular or corrugated sample surfaces

– Polarization

Suitable for observing the polarization characteristics of samples, presenting sharp contrast and color

*Be comparable to OLYMPUS DSX1000 Digital Microscope All in One